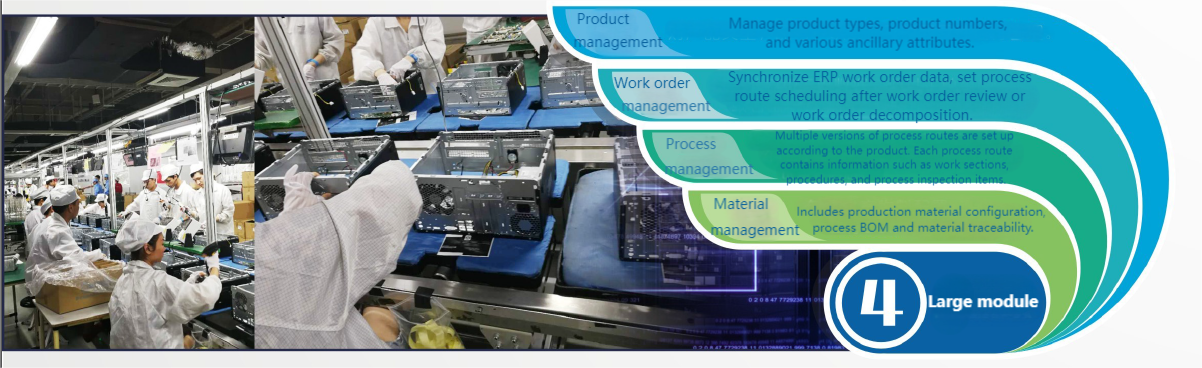

Yunxin PCS process control system integrates the information functions related to manufacturing, mainly including: user authority management, basic data management, production order management, production process control, external system interface and API, production process data query and traceability, quality statistical reports, etc. It helps small and medium-sized manufacturing companies solve problems in production orders, processes, material management and production data collection, and take the first step towards manufacturing informatization.

PCS Core Module

-

01

Progress Report

The production dispatch, process, personnel, quality inspection and other information are linked in an orderly manner through the barcode system, so that all production progress can be monitored in real time.

-

02

Process level control

By creating a unique mark for each (batch) product through barcodes, and by keeping accurate production records for each process, the flow of production links can be traced, product files can be obtained in real time, and traceability problems can be solved.

-

03

Visualize the production process

Visualized production process: The execution status of all work orders in process is presented on the screen, making the entire production process visible and controllable, reducing communication costs and ensuring delivery schedule requirements.

-

04

Real-time production dashboard

The production dashboard can timely display the progress of each work order, production quality analysis and the communication of various production instructions, thereby improving production efficiency and reducing production management costs.

-

05

Product Advantages

Integrated production, safe and reliable data, simple and easy to use, fast and convenient deployment, rich scalability, and efficient consulting services.

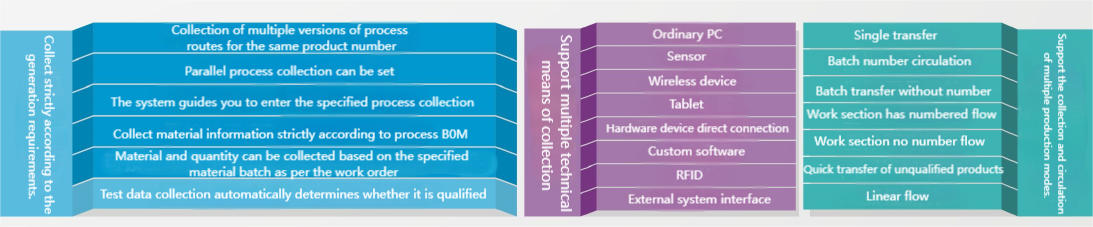

Automated and intelligent data collection