Yunxin MES system takes the data integration of the entire workshop as the core and production tracking as the main line, and comprehensively controls the workshop production business such as production planning management, process flow management, material management, resource management, logistics management, quality management, equipment management, test interface management, production work order management, data collection, statistical analysis, automatic alarm (early warning), etc. Yunxin MES system is a complex and large production management system, which manages the production process meticulously through numerous functional modules. However, each manufacturing enterprise often hopes to adopt the strategy of "small steps and slow running, step-by-step implementation" according to its own scale or production characteristics. In order to adapt to market demand, Yunxin MES system has been designed in a modular way to reduce the degree of coupling between modules, and can be implemented gradually in a flexible expansion manner. The MES system grows with the enterprise, thereby reducing the implementation risk, implementation difficulty and cost of the project.

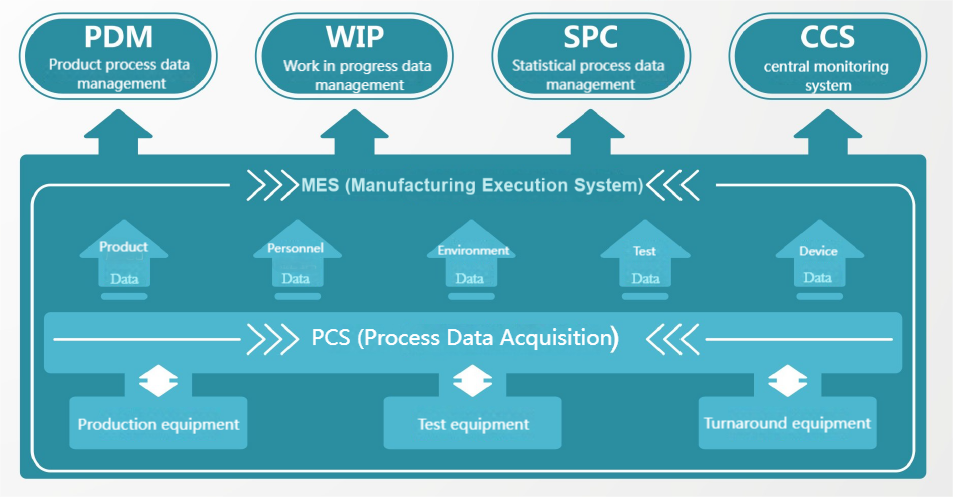

Yunxin MES system architecture

Yunxin MES Functional Module

-

01

Progress Report

The production dispatch, process, personnel, quality inspection and other information are linked in an orderly manner through the barcode system, so that all production progress can be monitored in real time.

-

02

Process level

By creating a unique mark for each (batch) product through barcodes, and by keeping accurate production records for each process, the flow of production links can be traced, product files can be obtained in real time, and traceability problems can be solved.

-

03

Visualization of the production process

Visualized production process: The execution status of all work orders in process is presented on the screen, making the entire production process visible and controllable, reducing communication costs and ensuring delivery schedule requirements.

-

04

Real-time production dashboard

The production dashboard can timely display the progress of each work order, production quality analysis and the communication of various production instructions, thereby improving production efficiency and reducing production management costs.

-

05

Product Advantages

Integrated production, safe and reliable data, simple and easy to use, fast and convenient deployment, rich scalability, and efficient consulting services.

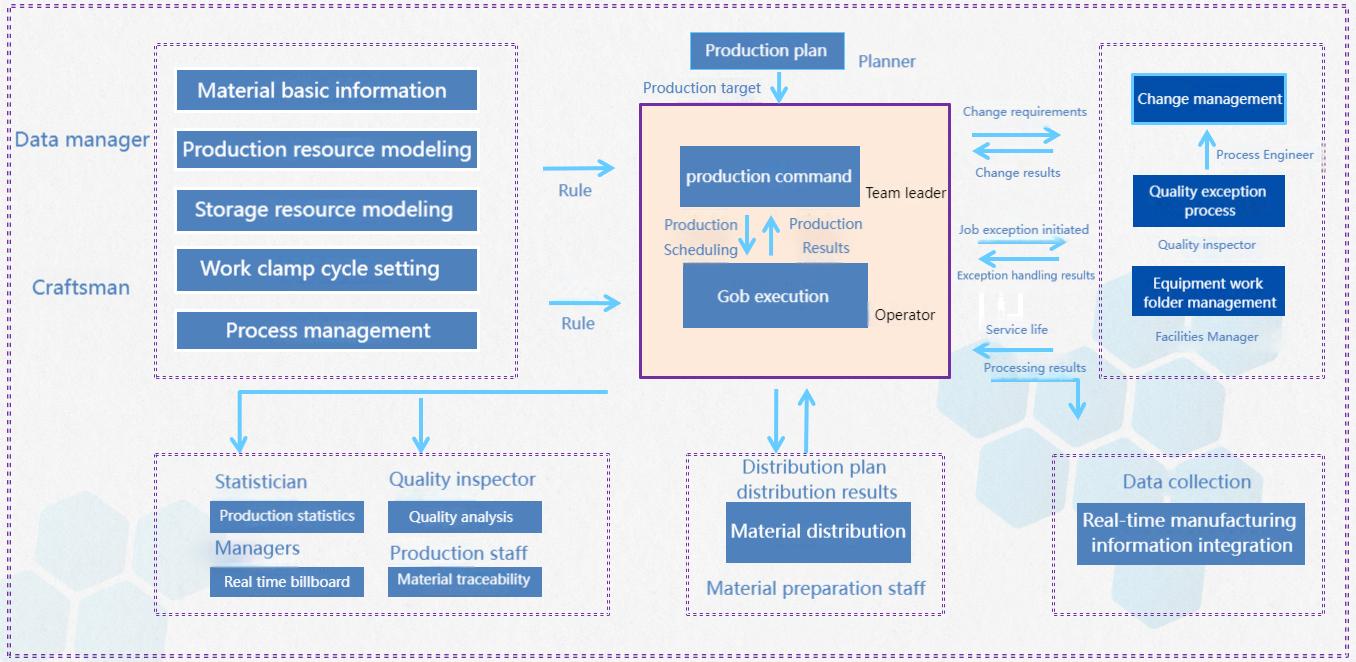

Production process data collection business logic